At Concentrol we carry out studies in our laboratories to evaluate the effectiveness of our solutions. Through these tests, we can observe the performance of the different products in our catalogue and compare them with the characteristics and results of competitive products. Thus, we can offer the best value for money on the market, while we solve the needs of the sector.

The results of two studies carried out at Concentrol laboratories are presented below. In the first, we will see the performance of EMULTROL DFM DV-1 S compared to a reference antifoaming agent on the market, using a dishwasher detergent as a medium. In the second one, the antifoaming effectiveness over time of EMULTROL DFM DV-30, EMULTROL DFM DV-1 and the competitor’s antifoaming agent is compared.

Both Concentrol products are high-performance solutions for adverse media with surfactants (high acidity or high alkalinity), such as detergents and fabric softeners.

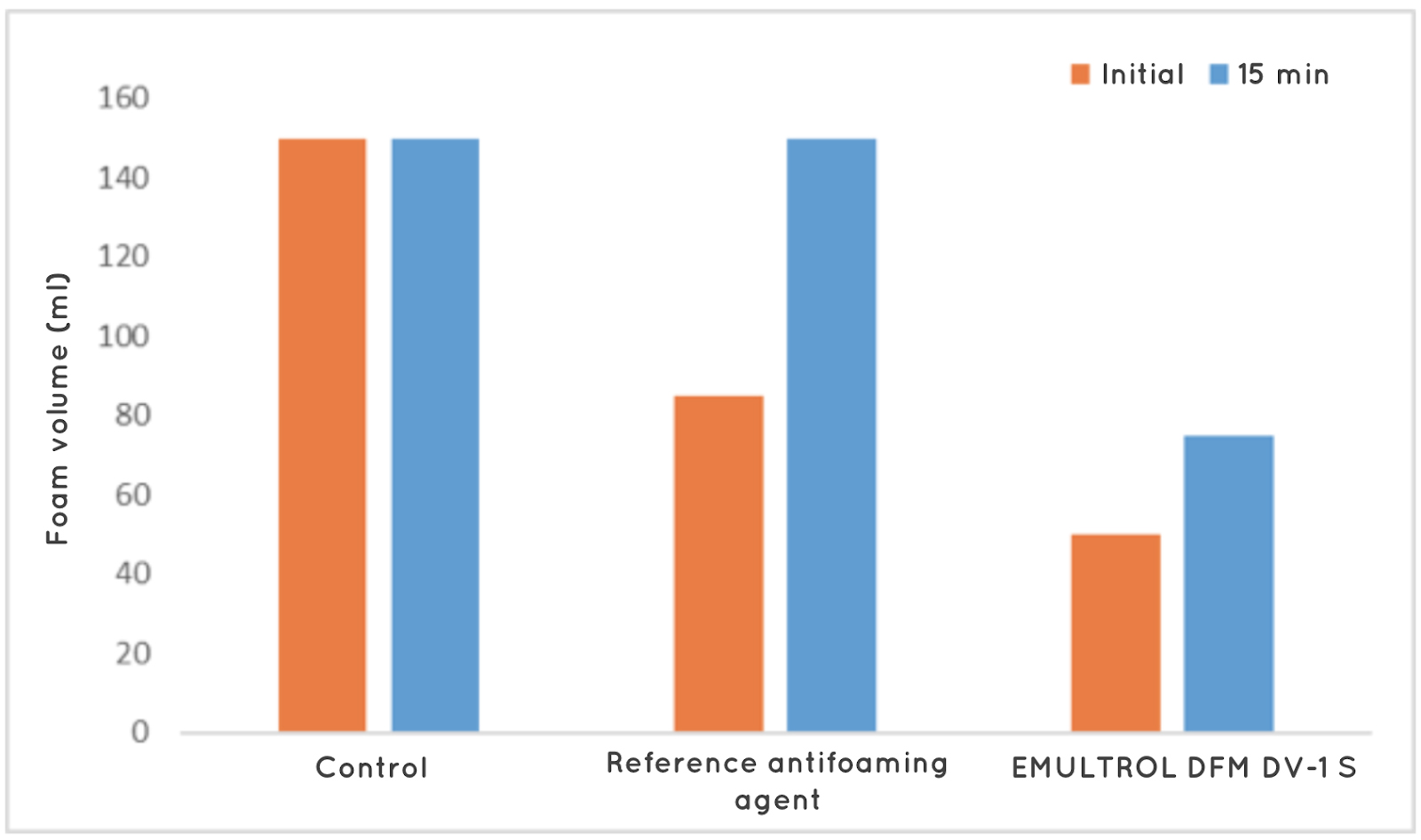

Comparative antifoaming test between Emultrol DFM DV-1 S and a market reference antifoaming agent in dishwasher detergent medium

In this study, the antifoaming effectiveness of the product EMULTROL DFM DV-1 S, manufactured by Concentrol, is compared to the antifoaming agent of the competition.

To determine the antifoaming effectiveness of the different products, macro-foam tests are carried out based on the compressed gas injection method, using dishwasher detergent as the medium.

Macrofoam formation test

To carry out the following study, the compressed gas injection method is chosen: 50 g of the detergent medium are weighed in a 200 ml maximum volume glass, the corresponding antifoam (dose 0.2%) is added and air is injected using a gas diffuser (pressure: 0.3 kg / cm2; flow rate: 0.05 l / min).

The increase in foam formed after 30 seconds is then measured. The test is repeated after 15 minutes to evaluate the stability of the antifoaming effect over time. The test concludes with these results:

Graph 1. This graph shows the volume of foam formed in the macro-foaming test in a dishwasher detergent medium with each of the different antifoaming agents used in this study.

As can be seen, the volume of foam formed from the medium without antifoaming agent quickly exceeds the volume of the beaker used (200 ml). Using the market reference antifoaming agent, it is observed that the amount of foam remains 80 ml after 30 seconds. However, if we repeat the macro-foaming test after 15 minutes, the volume of foam exceeds the volume of the glass.

As can be seen, the volume of foam formed from the medium without antifoaming agent quickly exceeds the volume of the beaker used (200 ml). Using the market reference antifoaming agent, it is observed that the amount of foam remains 80 ml after 30 seconds. However, if we repeat the macro-foaming test after 15 minutes, the volume of foam exceeds the volume of the glass.

On the other hand, the EMULTROL DFM DV-1 S antifoaming agent shows an ability to maintain a foam volume of 50 ml and, repeating the test after 15 minutes, it manages to maintain the foam at 75 ml.

The tests were also carried out after 1 hour, but no antifoaming agent was able to keep the foam under control, so it follows that it lost its effect.

Conclusions

The antifoaming agent Emultrol DFM DV-1 S is recommended not only because it shows a better immediate antifoaming effect compared to the market reference antifoam, but also for its greater stability over time in a medium with an alkaline pH such as dishwasher detergent.

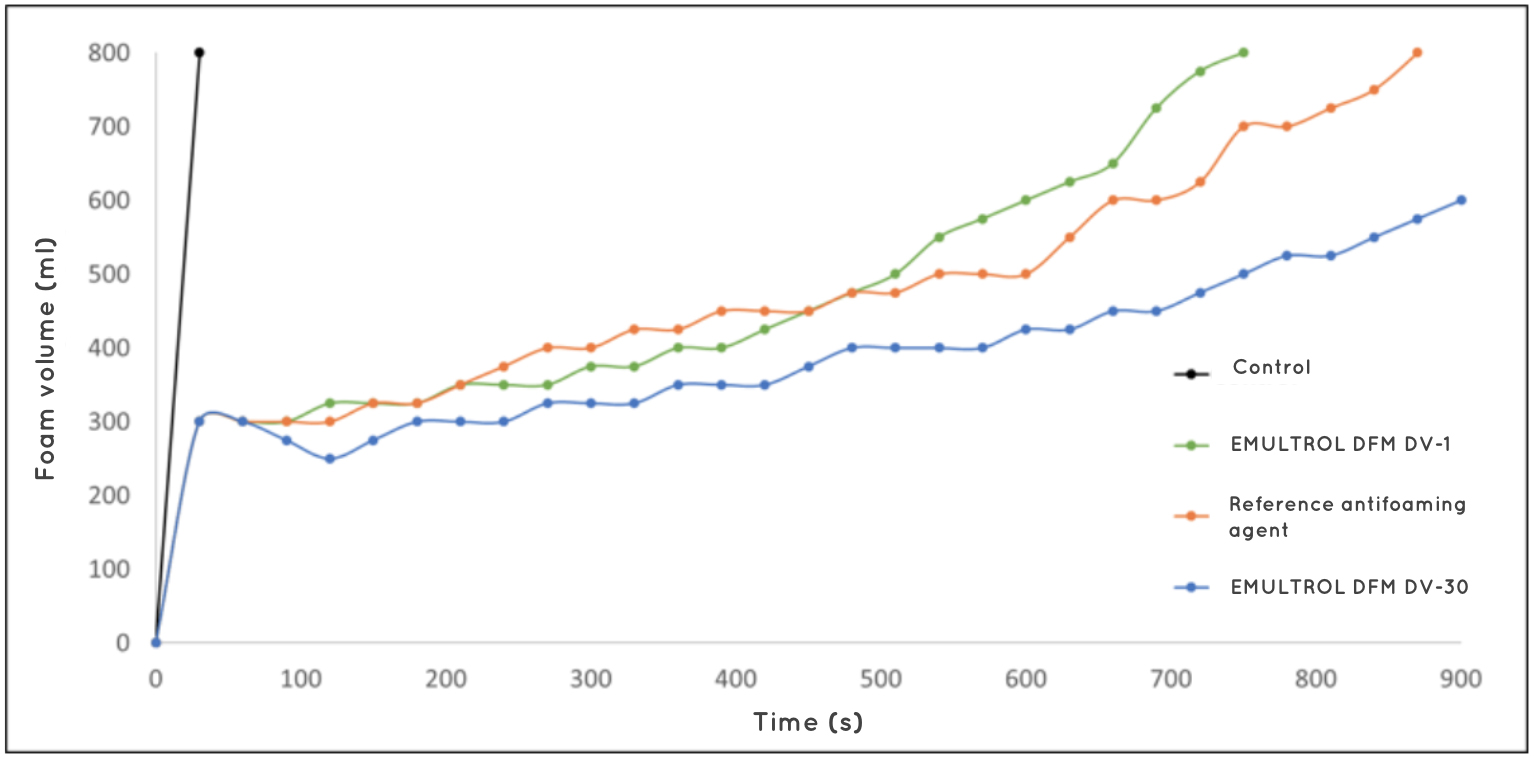

Comparative study of antifoaming agents for fabric softener with Emultrol DFM DV-30, Emultrol DFM DV-1 and a product from the competition

The present study compares the antifoaming effectiveness over time of the antifoaming agents Emultrol DFM DV-30, Emultrol DFM DV-1 and one from the competition.

Comparing the composition of the products in this study, the competitor’s antifoaming agent is an aqueous emulsion of silicone and other components with a solid concentration of 30%.

On the other hand, the two Concentrol products compared in this study are based on aqueous silicone emulsions, Emultrol DFM DV-30 and Emultrol DFM DV-1, which contain: 30% and 17% solids respectively. The viscosities of the studied products are shown below in Table 1.

Table 1. The product, composition and solid content of the different antifoaming agents tested in the present study.

| Product | Composition | Dry extract (%) | Rotational viscosity at 50 rpm (cps) |

| Common antifoaming agent on the market | Aqueous silicone emulsion | 30 | 1800 |

| EMULTROL DFM DV-30 | Aqueous silicone emulsion | 30 | 3500 |

| EMULTROL DFM DV-1 | Aqueous silicone emulsion | 17 | 850 |

To determine the effectiveness of the different antifoaming agents, macro-foam tests are carried out, based on the gas injection method. The foaming medium is an aqueous dilution with a factor of 1/5 of the neutral softener base, without antifoaming agents.

Methodology

For the present study, the gas injection method has been used. First, 200 ml are measured on average in a 1000 ml beaker, under conditions of room temperature 25 °C and magnetic stirring of 1000 rpm. Subsequently, the corresponding antifoam is added with a dose of 0.025%. Immediately after dosing the antifoaming agent, the gas is injected through a gas diffuser (pressure: 1 kg / cm2; flow rate: 0.1 l / min). The volume of the foam formed is then measured, at 30-second intervals, over 15 minutes.

Graph 1. The volume of foam formed over time is compared with antifoaming agents based on silicone emulsions with different concentration of solids, in a softener base.

As can be seen, the control test shows a rapid increase in foam volume, while the tests with the different silicone antifoaming agents in aqueous emulsion are able to maintain a level of foam without great differences in the first 5 minutes.

In the long term, the differences in the volume of foam generated are accentuated, showing how Emultrol DFM DV-30 maintains the best long-term effectiveness followed by the antifoam of the competition. Finally, the antifoam Emultrol DFM DV-1 shows a very efficient antifoam capacity due to its reduced amount of solids compared to the other products compared in this study.

Conclusion

In summary, the antifoaming agent Emultrol DFM DV-30 is shown to be the most effective, compared to the antifoam from the competition, which contains a similar amount of solids. On the other hand, Emultrol DFM DV-1 proves to be the most efficient antifoaming agent due to its optimal effectiveness/solids ratio.

As we have been able to validate in these studies, the Concentrol products Emultrol DFM DV-30 and Emultrol DFM DV-1 are not only effective when applied, but also effective after a while. That is, they continue to break the foam for a few minutes, enough time to be able to carry out an effective packaging.

At Concentrol we are clear that one of the strengths of our DNA is our commitment to knowledge. Thanks to the work by our laboratory technicians, we are able to carry out constant checks to evaluate the results of our products. This allows us to offer good value for money and meet the needs of all our clients in 82 countries and on 5 continents.